|

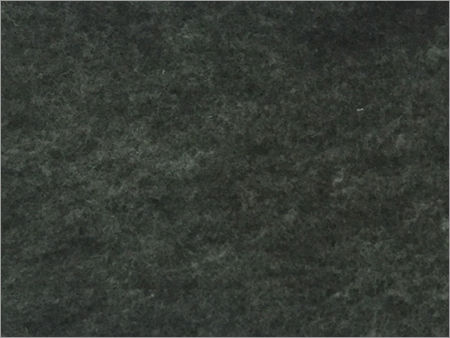

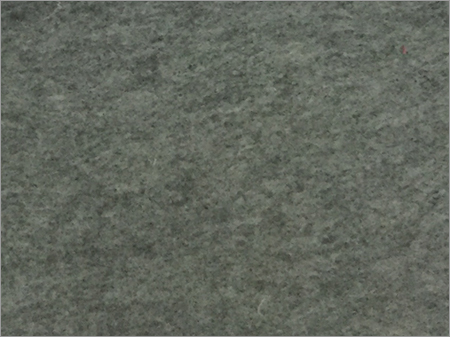

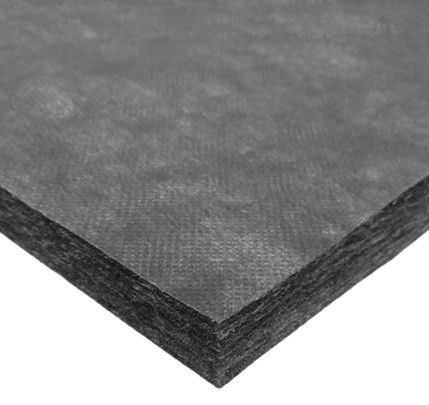

Sandwich Felt Side

Sandwich Felt Side Specification

- Feature

- High Durability, Abrasion Resistant

- Temperature Resistance

- Up to 150C

- Pattern

- Solid

- Width

- Customizable, up to 2 meters

- Coating Material

- Non-Coated

- Density

- 0.40 Gram per cubic centimeter(g/cm3)

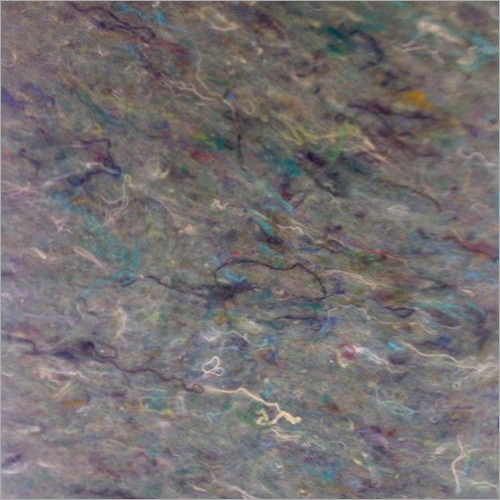

- Material

- Wool, Synthetic Blend

- Texture

- Soft, Compressed

- Style

- Plain, Industrial

- Technique

- Needle Punched, Pressed

- Theme

- Industrial Processing

- Type

- Sandwich Felt Side

- Thickness

- 5 mm - 40 mm

- Color

- Grey, Off White

- Use

- Gasket, Sealing, Padding, Industrial Machinery

- Compression Strength

- 12 kPa - 35 kPa

- Application Areas

- Automotive, Engineering, Textile, Printing Industry

- Flame Retardancy

- Basic (non-flammable treated options available)

- Minimum Order Quantity

- 100 kgs

- Oil Resistance

- Moderate

- Shore Hardness

- Flexible

- Water Absorption

- Low

- Elongation at Break

- Minimal, less than 5%

- Packaging Type

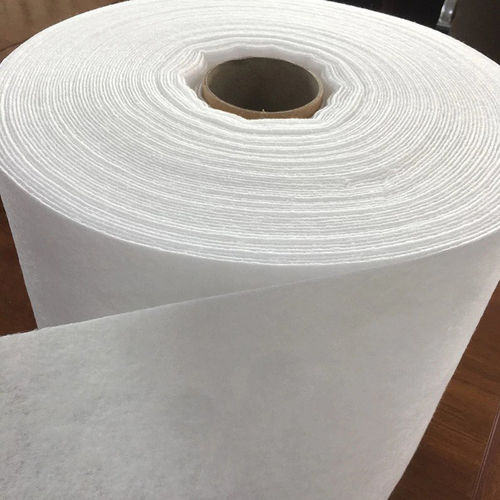

- Rolls/Bales

- Sound Absorption

- High, suitable for noise dampening

Sandwich Felt Side Trade Information

- Minimum Order Quantity

- 1000 Kilograms

- Payment Terms

- Cash Advance (CA), Telegraphic Transfer (T/T), Cash in Advance (CID), Cheque

- Sample Available

- Yes

- Sample Policy

- Contact us for information regarding our sample policy

- Main Domestic Market

- All India

About Sandwich Felt Side

We are one of the prime manufacturers and suppliers of Sandwich Felt Side which is widely used in automobile industry for different purpose such as oil absorbing, sealing as well as sound damping. It is made using premium quality fibers at our production unit under the supervision of adept professionals. This felt is highly praised in market due to its enhanced durability as well as optimum thickness. Sandwich Felt Side is also available in customized options.

Features:

- Smooth finish

- Dimensional accuracy

- Abrasion resistant

Superior Noise Dampening Solution

Designed for applications with strict acoustic standards, Sandwich Felt Side offers exceptional sound absorption capabilities. Its dense, needle-punched construction significantly reduces noise transmission, making it an excellent choice for automotive cabins, industrial machinery, and printing equipment. The soft yet compressed texture ensures high performance in environments where noise reduction is a priority.

Versatile and Durable Material

With a blend of wool and synthetic fibers, this felt combines high durability with flexibility. The plain, solid style, customizable thickness, and color options offer great versatility for engineers, textile professionals, and manufacturers. Its abrasion resistance and ability to withstand temperatures up to 150C provide long-lasting reliability even in the most demanding industrial applications.

Reliable and Safe for Industrial Use

Sandwich Felt Side features low water absorption, moderate oil resistance, and flame-retardant options for enhanced safety. Cut to size up to 2 meters wide and offered in bulk roll or bale packaging, it meets the volume and application needs of large-scale manufacturing. These properties make it especially suited for gasket, sealing, and padding duties in varied processing environments.

FAQs of Sandwich Felt Side:

Q: How is Sandwich Felt Side typically used in industrial environments?

A: Sandwich Felt Side is commonly used for gasket making, sealing, padding, and noise dampening in automotive, engineering, textile, and printing industries, thanks to its compression strength, high durability, and sound absorption properties.Q: What benefits does this felt provide for noise reduction?

A: Its high sound absorption and dense, compressed structure make Sandwich Felt Side effective for noise dampening, helping reduce unwanted sound in automotive cabins, industrial machines, and processing units.Q: When should this material be considered for sealing applications?

A: Choose Sandwich Felt Side when you need a durable, flexible, and abrasion-resistant material that holds up well under compression, resists water and oil moderately, and maintains its integrity under temperatures up to 150C.Q: Where can I order Sandwich Felt Side and what is the minimum quantity?

A: Sandwich Felt Side is available directly from manufacturers and suppliers in India. The minimum order quantity is 100 kilograms, making it well-suited for both large and medium-scale industrial needs.Q: What is the production technique used for this industrial felt?

A: This felt is produced using needle punching and pressing techniques. These processes create a soft yet highly compressed texture, ensuring strength, flexibility, and consistent thickness throughout the roll or bale.Q: How can the size and shape of Sandwich Felt Side be customized?

A: Thickness between 5 mm and 40 mm and widths up to 2 meters are available, allowing for tailored solutions in a range of industrial applications. Rolls and bales can be supplied uncoated, as required by the user.Q: What are the key performance features that distinguish this felt from others?

A: Sandwich Felt Side stands out with its high abrasion resistance, minimal elongation, robust compression strength, temperature endurance up to 150C, and customizable dimensions, making it ideal for challenging industrial settings.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Automobile Felt Category

Grey Thermoplastic Felt

Minimum Order Quantity : 1000 Kilograms

Thickness : 2 mm 10 mm

Material : Other, Thermoplastic Felt

Temperature Resistance : 80C 120C

Pattern : Solid

Technique : Needle punched

Thermoplastic Felt

Minimum Order Quantity : 1000 Kilograms

Thickness : 1 mm to 10 mm (customizable)

Material : Other, Thermoplastic Fibers

Temperature Resistance : Up to 150C

Pattern : Plain

Technique : Heat Pressed/Molded

Brown Resinated Felt

Minimum Order Quantity : 1000 Kilograms

Thickness : 3 mm 10 mm (Customizable)

Material : Other, Resinated Felt

Temperature Resistance : 40C to 120C

Pattern : Plain

Technique : Resinated / Impregnation Process

Green Resinated Felt

Minimum Order Quantity : 1000 Kilograms

Thickness : 3 mm 25 mm

Material : Other, Resinated Felt

Temperature Resistance : Up to 180C

Pattern : Solid

Technique : Mechanically Pressed and Chemically Bonded

|

J.L. CHAWLA INTERNATIONAL

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Send Inquiry

Send Inquiry