|

Fiberglass Felts

Fiberglass Felts Specification

- Coating Material

- Silicone or PTFE (Optional)

- Density

- 120 Gram per cubic centimeter(g/cm3)

- Pattern

- Plain

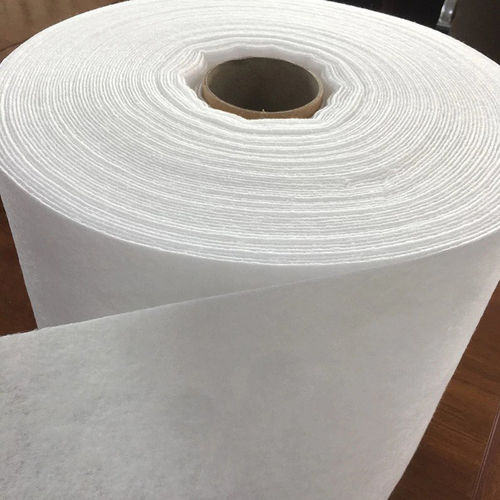

- Width

- 1 m to 2 m

- Temperature Resistance

- Up to 600C

- Feature

- High Strength, Fire Resistant

- Material

- Fiberglass

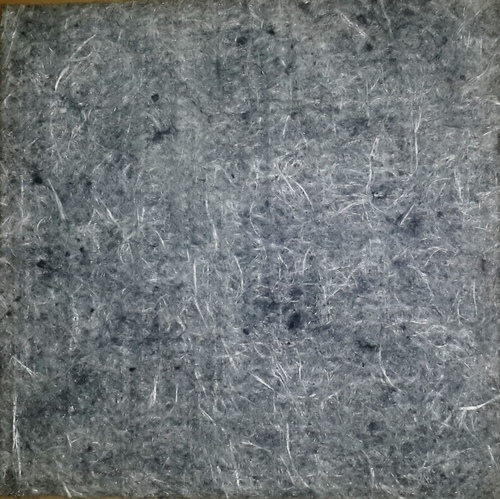

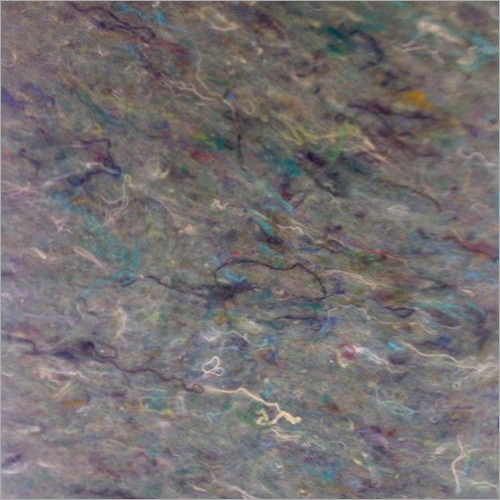

- Texture

- Nonwoven

- Style

- Felt

- Technique

- Needle Punched

- Theme

- Industrial

- Type

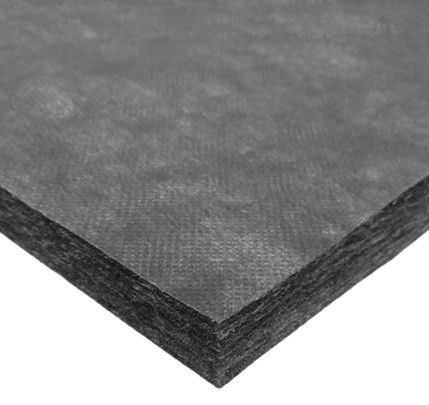

- Insulation Sheet

- Thickness

- 3 mm to 20 mm

- Color

- White/Grey

- Use

- Thermal and Acoustic Insulation

Fiberglass Felts Trade Information

- Minimum Order Quantity

- 1000 Kilograms

- Payment Terms

- Telegraphic Transfer (T/T), Cash in Advance (CID), Cheque, Cash Advance (CA)

- Delivery Time

- 1 Week

- Sample Available

- Yes

- Sample Policy

- Contact us for information regarding our sample policy

- Packaging Details

- As per Buyer Requirement

- Main Export Market(s)

- Australia, North America, Eastern Europe, Africa, Western Europe, Central America, Middle East, South America, Asia

- Main Domestic Market

- All India

- Certifications

- ISO 9001"2008

About Fiberglass Felts

Established in the year 2004, our enterprise has gained immense recognition in manufacturing, exporting and supplying the outstanding quality Polypropylene Felt, Fiberglass Felt. Provided felt is manufactured by utilizing optimal quality polypropylene material and advanced technology under the direction of our professionals. This felt is extensively used in various water proofing and damp-proofing applications. Furthermore, our esteemed clients can avail this Polypropylene Felt, Fiberglass Felt from us at the most reasonable rates.

Features:

- Simple installation

- Superior finish

- Less maintenance

- Non-inflammable

Outstanding Thermal and Fire Resistance

These fiberglass felts handle temperatures ranging from -40C up to 600C, making them excellent choices for insulation in high-temperature environments. Their inherent fire-resistant properties add another layer of protection, ensuring safety when used in industrial facilities, power plants, or automotive systems.

Durable and Chemically Resistant Structure

Engineered to withstand harsh conditions, these felts show impressive resistance to most acids and alkalis and maintain strength with tensile ratings above 500 N/5 cm. Their nonwoven structure, minimal moisture absorption, and optional surface coatings provide durability even in chemically aggressive or humid settings.

Versatile, Eco-Friendly Industrial Applications

Available in various thicknesses, densities, and widths, these felts are packaged as rolls or sheets and suit many insulation applications. Asbestos-free and manufactured to ASTM C553 standards, they offer reliable solutions for thermal and acoustic insulation across construction, power, automotive, and foundry sectors.

FAQs of Fiberglass Felts:

Q: How are fiberglass felts typically installed in industrial applications?

A: Installation involves cutting the roll or sheet to fit required dimensions and fastening it to the target surface using mechanical anchors, adhesives, or banding. Suitable for walls, pipelines, equipment, or automotive components, the felt is easy to shape and install due to its nonwoven texture.Q: What makes these fiberglass felts suitable for high-temperature environments?

A: With a service temperature range of -40C to +600C and fire-resistant properties, these felts maintain structural integrity and insulation performance even under intense heat, making them ideal for power plants, foundries, and similar industrial settings.Q: When should a silicone or PTFE coating be chosen for fiberglass felts?

A: A silicone or PTFE coating is recommended when additional chemical resistance or a smoother, non-stick surface is desired, especially in environments with frequent exposure to oils, chemicals, or where easy cleaning is necessary.Q: Where can fiberglass felts be used for optimal acoustic and thermal insulation?

A: These felts excel in environments such as machinery enclosures, wall partitions, ductwork, and automotive firewalls where both thermal and sound insulation are required, providing energy savings and noise reduction.Q: What are the benefits of using asbestos-free fiberglass felts in construction and industry?

A: Being asbestos-free ensures user safety and environmental friendliness, reducing health risks associated with inhaling hazardous fibers while maintaining excellent insulation performance and compliance with international safety standards.Q: How do you ensure the supplied felt meets ASTM C553 standards?

A: Manufacturers rigorously test physical and thermal properties, such as density, tensile strength, and fire resistance, to ensure each batch adheres to ASTM C553 requirements, providing reliability and quality assurance to users.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Mouldable Felts Category

Acoustic Felt

Minimum Order Quantity : 1000 Kilograms

Thickness : 9 mm

Style : Other, Modern

Feature : EcoFriendly, NonToxic, Fire Retardant, High Acoustic Performance

Texture : Other, Soft Matte Finish

Use : Wall Paneling, Ceilings, Sound Absorption, Interior Decoration

|

J.L. CHAWLA INTERNATIONAL

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Send Inquiry

Send Inquiry