|

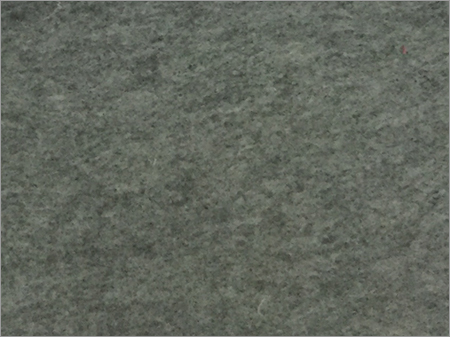

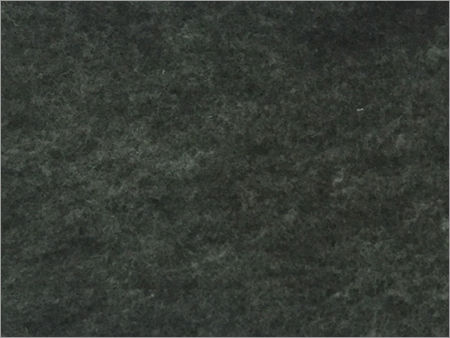

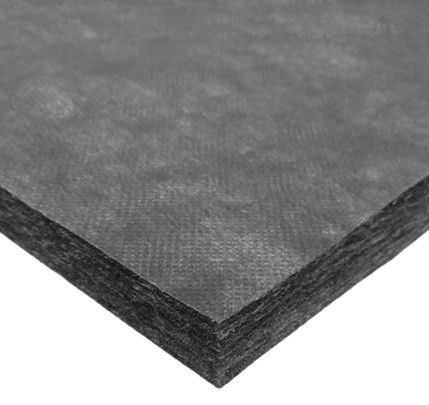

Grey Thermoplastic Felt

Grey Thermoplastic Felt Specification

- Width

- Up to 2000 mm

- Temperature Resistance

- 80C - 120C

- Feature

- Durable, Flexible, Tear Resistant

- Pattern

- Solid

- Coating Material

- Uncoated

- Density

- 450 Gram per cubic centimeter(g/cm3)

- Material

- Thermoplastic Felt

- Texture

- Non-woven, Uniform

- Style

- Plain

- Technique

- Needle punched

- Theme

- Industrial

- Type

- Grey Thermoplastic Felt Sheet

- Thickness

- 2 mm - 10 mm

- Color

- Grey

- Use

- Automotive, Insulation, Filtration, Upholstery

- Eco-Friendly

- Recyclable and non-toxic

- Length

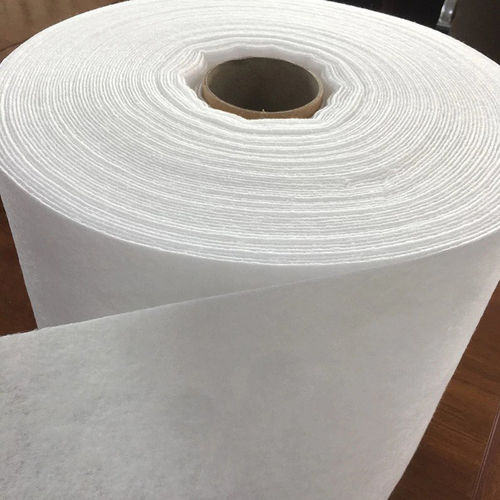

- Customizable, typically in rolls

- Shrinkage

- Minimal under designated temperature range

- Odor

- Odorless

- Abrasion Resistance

- High

- Mouldability

- Excellent, easily thermoformed

- Water Absorption

- Low

- Surface Finish

- Smooth, uniform surface

- Flame Retardant

- Available upon request

- Sound Insulation

- Effective sound dampening properties

- Moisture Resistance

- Good

- UV Resistance

- Moderate

- Tensile Strength

- Strong, suitable for industrial use

Grey Thermoplastic Felt Trade Information

- Minimum Order Quantity

- 1000 Kilograms

- Payment Terms

- Telegraphic Transfer (T/T), Cash in Advance (CID), Cheque, Cash Advance (CA)

- Sample Available

- Yes

- Sample Policy

- Contact us for information regarding our sample policy

- Main Domestic Market

- All India

About Grey Thermoplastic Felt

To provide utmost satisfaction to our clients, we have been involved in manufacturing and supplying Grey Thermoplastic Felt. It is broadly utilized for lining of roof, boot compartment, rear shelf doors as well as engine compartment of automobiles. This felt is checked on different standard parameters such as quality and durability. It is well known in market due to its fine finish and optimum thickness. Grey Thermoplastic Felt can also be availed in customized options as per clients demand.

Features:

- High strength

- Long service life

- Resistance against heat

Thermoplastic Felt for Industrial Excellence

Engineered for demanding industrial applications, Grey Thermoplastic Felt delivers robustness and adaptability. Its exceptional mouldability allows easy thermoforming, ensuring a perfect fit for automotive interiors, insulation panels, and filtration systems. The felts plain, uniform texture and smooth surface result from advanced needle-punched manufacturing, contributing to superior product consistency.

Eco-Friendly and Safe Material Choice

This thermoplastic felt aligns with sustainable practices, being both recyclable and non-toxic. It is odorless and offers optional flame-retardant properties for enhanced safety. Its minimal shrinkage and moderate UV resistance optimize performance in various environments, while its moisture-resistant and sound-insulating qualities support versatile industrial uses.

FAQs of Grey Thermoplastic Felt:

Q: How is Grey Thermoplastic Felt typically installed or used in industrial applications?

A: Grey Thermoplastic Felt is supplied in rolls, enabling easy cutting, thermoforming, or layering to meet precise requirements for automotive, insulation, filtration, or upholstery tasks. Its excellent mouldability allows it to be shaped and mounted using heat or adhesives, ensuring secure and efficient installation.Q: What are the main benefits of using Grey Thermoplastic Felt in automotive and insulation projects?

A: The felts high abrasion resistance, strong tensile strength, effective sound dampening, and moisture resistance make it especially valuable for automotive interiors and insulation panels. Additionally, its smooth, odorless, and non-toxic nature ensures user comfort and contributes to a safer environment.Q: When should optional flame retardant features be considered for this felt material?

A: Flame retardant properties are recommended when the felt will be exposed to potential ignition sources, such as in vehicle interiors or electrical insulation zones. This feature enhances fire safety and can be requested during order placement for tailored protection.Q: Where can Grey Thermoplastic Felt be sourced or supplied?

A: This industrial felt is manufactured and supplied in India, with customizations available for size, thickness, and roll length. Reputable suppliers cater to various industries and can provide technical support for customized applications.Q: What is the process behind manufacturing Grey Thermoplastic Felt?

A: The felt is made through a needle-punched process, where thermoplastic fibers are mechanically entangled to form a uniform, solid material. This technique enhances strength and durability while ensuring a consistent, smooth surface ideal for demanding industrial uses.Q: How does the felts temperature and moisture resistance affect its usage?

A: With a temperature resistance range of 80C to 120C and good moisture resistance, the felt maintains its structural integrity and performance in both dry and humid conditions. This reliability makes it suitable for a wide range of industrial environments, from automotive workshops to damp filtration setups.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Automobile Felt Category

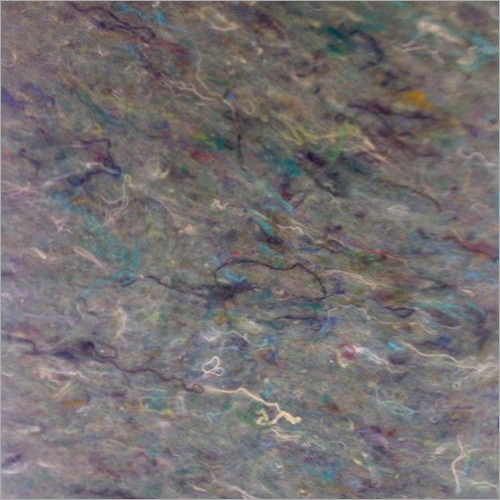

Sandwich Felt Side

Minimum Order Quantity : 1000 Kilograms

Type : Sandwich Felt Side

Texture : Other, Soft, Compressed

Theme : Industrial Processing

Color : Grey, Off White

Density : 0.40 Gram per cubic centimeter(g/cm3)

Green Resinated Felt

Minimum Order Quantity : 1000 Kilograms

Type : Green Felt Sheet

Texture : Other, Soft and Even

Theme : Industrial Utility

Color : Green

Density : 0.40 Gram per cubic centimeter(g/cm3)

Brown Resinated Felt

Minimum Order Quantity : 1000 Kilograms

Type : Brown Felt Sheet

Texture : Other, Smooth and Dense

Theme : Solid

Color : Brown

Density : 0.28 Gram per cubic centimeter(g/cm3)

Thermoplastic Felt

Minimum Order Quantity : 1000 Kilograms

Type : Thermoplastic Felt Sheet

Texture : Other, Nonwoven Felt

Theme : Functional

Color : White / Grey (standard), Custom colors available

Density : 0.30 Gram per cubic centimeter(g/cm3)

|

J.L. CHAWLA INTERNATIONAL

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Send Inquiry

Send Inquiry