|

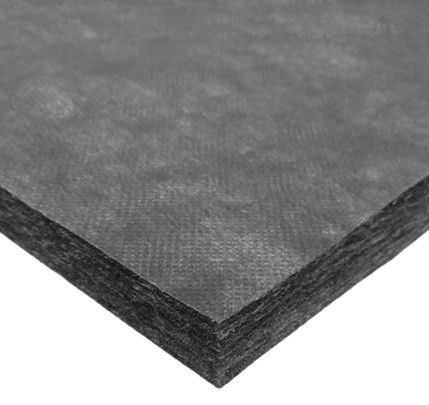

Sandwich Felt

Sandwich Felt Specification

- Coating Material

- Uncoated/Custom Coating Available

- Temperature Resistance

- Up to 180C

- Density

- 0.5 Gram per cubic centimeter(g/cm3)

- Width

- Up to 2000 mm

- Pattern

- Flat/Uniform

- Feature

- High Durability, Non-Toxic, Lightweight

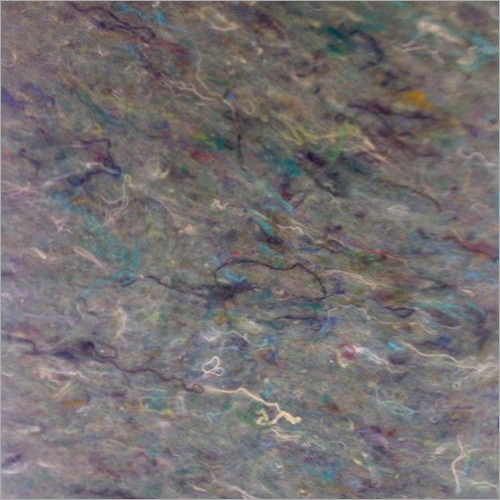

- Material

- Synthetic Fiber and Wool Blend

- Texture

- Soft and Smooth

- Style

- Plain

- Technique

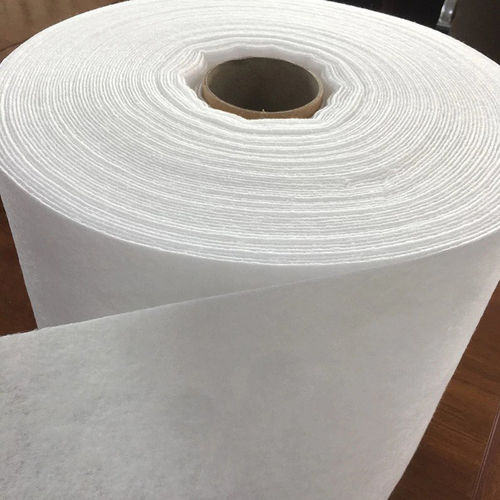

- Needle Punched

- Theme

- Industrial

- Type

- Sandwich Felt Sheet

- Thickness

- 3-30 mm

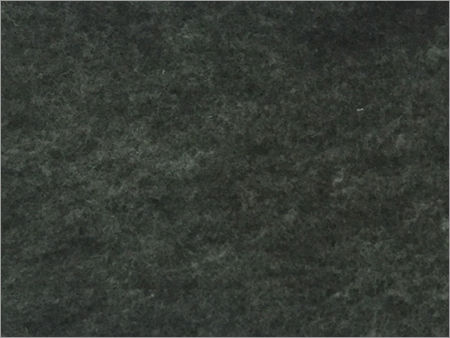

- Color

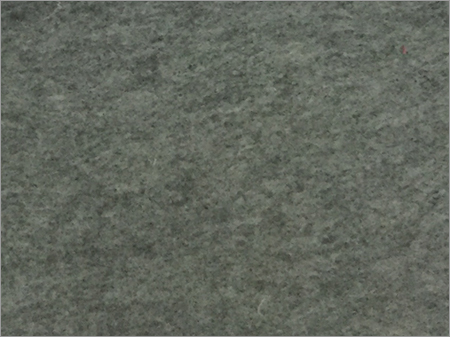

- Multi-Color (White, Grey, Black, Customizable)

- Use

- Gasket, Insulation, Polishing, Padding, Filtration

Sandwich Felt Trade Information

- Minimum Order Quantity

- 1000 Kilograms

- Payment Terms

- Telegraphic Transfer (T/T), Cash in Advance (CID), Cheque, Cash Advance (CA)

- Sample Available

- Yes

- Sample Policy

- Contact us for information regarding our sample policy

- Main Domestic Market

- All India

About Sandwich Felt

To serve clients in best possible manner, we have been involved in manufacturing and supplying Sandwich Felt. It is made using quality material which is procured from reliable market vendors. Offered felt is widely demanded in automobile industry for sound dampening as well as oil absorbing. It is strictly checked on different standard parameters such as quality and durability. Sandwich Felt can also be availed in different specifications and is known for its long service life.

Features:

- Requires less maintenance

- Resistance against abrasion

- Unmatched quality

Fire-Resistant and Durable for Industrial Demands

Our sandwich felt sheets cater to rigorous industrial environments with excellent fire resistance (available on request), high compression strength, and enhanced tensile properties. These characteristics ensure longevity and safety, minimizing downtime and maintenance, making them an optimal choice for insulation, padding, and filtration uses.

Custom Options for Precise Fit

Designed for flexibility, these felts come in multiple shapes and thicknesses (330 mm), and can be customized in color, size, and density. Whether you need sheets, rolls, or custom-cut pieces, we offer tailored solutions to match unique industrial needs, guaranteeing consistent performance and seamless application.

Sustainable and Safe Material Choice

Made from a synthetic fiber and wool blend, our sandwich felt is both eco-friendly and recyclable. Equipped with a non-toxic, odorless profile and long shelf life of up to five years, it ensures safety for workers and the environment while delivering reliability for long-term industrial use.

FAQs of Sandwich Felt:

Q: How is the fire resistance feature incorporated into sandwich felt?

A: The sandwich felt can be specially treated for fire resistance upon request during manufacturing. This enhances the materials safety against high-temperature environments without compromising its other industrial properties.Q: What makes this felt suitable for industrial applications?

A: Its high compression and tensile strength, fine surface finish, effective acoustic insulation, and temperature resistance up to 180C ensure the material can withstand rigorous, continuous industrial operations.Q: Can I customize the size, color, or density of the sandwich felt sheets?

A: Yes, you can request custom sizes (up to 2000 mm width), colors (including white, grey, black, or custom shades), and densities to fit your exact requirements for different industrial purposes.Q: When should I choose sandwich felt over other materials?

A: Sandwich felt is ideal when you need a non-toxic, odorless, lightweight material that offers high durability, sound dampening, fire resistance (if requested), and low moisture absorption in applications like gaskets, insulation, and filtration.Q: Where can this felt be used within industrial settings?

A: Common uses include gaskets, acoustic insulation, polishing, padding, filtration, and as general-purpose industrial sheets, thanks to its versatile properties and customizable options.Q: What processes are involved in manufacturing the sandwich felt?

A: The felt is produced using a needle-punched technique, blending synthetic fibers with wool to ensure softness and durability while achieving the desired thickness, density, and surface quality.Q: What are the benefits of using eco-friendly, recyclable felt in industry?

A: Using eco-friendly, recyclable felt supports sustainable manufacturing practices, reduces environmental impact, and helps companies meet regulatory standards, all while maintaining robust performance and long shelf life.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Automobile Felt Category

Green Resinated Felt

Minimum Order Quantity : 1000 Kilograms

Temperature Resistance : Up to 180C

Material : Other, Resinated Felt

Theme : Industrial Utility

Texture : Other, Soft and Even

Color : Green

Thermoplastic Felt

Minimum Order Quantity : 1000 Kilograms

Temperature Resistance : Up to 150C

Material : Other, Thermoplastic Fibers

Theme : Functional

Texture : Other, Nonwoven Felt

Color : White / Grey (standard), Custom colors available

Brown Resinated Felt

Minimum Order Quantity : 1000 Kilograms

Temperature Resistance : 40C to 120C

Material : Other, Resinated Felt

Theme : Solid

Texture : Other, Smooth and Dense

Color : Brown

Grey Thermoplastic Felt

Minimum Order Quantity : 1000 Kilograms

Temperature Resistance : 80C 120C

Material : Other, Thermoplastic Felt

Theme : Industrial

Texture : Other, Nonwoven, Uniform

Color : Grey

|

J.L. CHAWLA INTERNATIONAL

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Send Inquiry

Send Inquiry